Here we presenting you detailed estimate formulas and some use ful informations.

Construction Estimating Formulas & Useful Information

Formulas, equations, tables, facts, specifications and other

information useful in planning and estimating construction,

decorating and other projects.

Measure of Dimensions,

Theorem ▪ Formulas, Rectangles,

Squares, Triangles & Circles ▪ Board Feet Concrete Estimating ▪ Decimal and Metric

Equivalents ▪ Weights, etc. ▪ Metrics ▪ Energy, Electric, Insulation ▪ Drywall

Estimating, Door Handing

Three dimensions of estimating:

Linear Measure

|

Square Measure

|

Cubic Measure

|

|

12 inches = 1 lineal

ft.

|

12" x 12" =

144sq" = 1sq ft.

|

12" x 12" x

12" = 1728 cu" = 1 cubic ft.

|

|

3 lineal feet = 1

yard.

|

3' x 3' = 9sq feet =

1sq yd.

|

3' x 3' x 3' = 27 cu

feet = 1 cubic yard.

|

|

5,280 lin ft = 1 mile.

|

43,560sq' = 1 acre.

|

36" x 36" x

36" = 46,656 cu" = 1 cubic yard.

|

|

Inches x .0833 = ft.

Inches / 12 = ft.

|

Sq" x .00694 = sq

ft.

|

Cu" x .0005787 =

cu'.

|

|

Inches x .2778 = yds.

|

Sq" x .007716 =

sq yds.

|

Cu' x .0002143 = cu

yds.

|

|

Feet x .3333 = yds.

|

Sq' x .11111 = sq yds.

|

Cu' x .03704 = cu yds.

|

|

|

100sq feet = 1 square

(measure used in roofing).

|

|

Useful Mathematical Formulas:

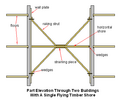

1. One of the most useful formulas is the

Pythagorean theorem. The theorem states that the square of the hypotenuse

of a right (90 degree angle) triangle is equal to the sum of the squares of its

legs.

For

Example: (3' x 3' = 9') + (4' x 4'

=16') = 25', √25=5

This can be used for a

wide variety of uses from squaring up a concrete form for a foundation, to

attaching a new addition squarely to an existing building, or measuring a

countertop -anywhere you must be certain of a right angle. Just plug in

your numbers and get a calculator that has a square root function.

2. The area of a rectangle is equal to its

base x height. (A = b x h).

For example: 10 x 5 = 50

3. The area of a square is equal to its base x height (see above).

-or-

The area of a square is equal to the square of one of its sides. (A = S

squared).

For example: 5²=25

4. The area of a triangle is equal to 1/2 the product of its base

and height. A = 1/2 (b x h).

For example: 10 x 10 = 100 x 1/2 = 50

5. Circles

The area of a circle is equal to 1/2 the product of its radius and

circumference. (A = 1/2 (r x c).

For

example:

radius = 5, circumference = 31.42: 5 x 31.42 = 157.1 x 1/2 = 78.55

-or-

A=π r², 3.1416(5 x 5) = 3.1416 x 25 =

78.54

-or-

A= d² x .7854

Find the circumference of a circle by multiplying the diameter x

(π). Find the volume of a cylinder by multiplying the height x the area

of the circle.

*π = 3.1416

The circumference of a

circle can be divided into equal parts with a calculator. This will allow

you to make proportioned shapes within the circle. For example -stars,

triangles, octagons, etc.

To find the divisions,

multiply the diameter of the circle by the following multipliers.

|

Division

|

Multiplier

|

|

Division

|

Multiplier

|

|

3

|

.86603

|

|

8 (Octagon)

|

.38268

|

|

4

|

.70711

|

|

9

|

.34202

|

|

5

|

.58779

|

|

10

|

.30902

|

|

6

|

.50000

|

|

11

|

.28173

|

|

7

|

.43388

|

|

12

|

.25882

|

For example:

21.166" x .38268 (from above table) = 8.099"

6. Board Feet: A board foot is essentially a

measure of wood, figured on the called size, not the actual finished

size. Therefore a 2" x 4" x 8" contains 5.33 bd. ft.

The theory is that you pay for what the mill started with before the wood is

dried and planed.

Thickness" x Width" x Length in feet, divided by 12 = board feet.

T" x W" x L" ÷ 12 = Board ft.

Thickness" x Width" x Length in inches divided by 144 = bd. ft.

(T" x W" x L") ÷ 144 = Board ft.

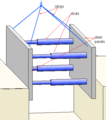

7. Concrete: Concrete is usually

measure in cubic yards. A cubic yard is 3' wide x 3' long x 3'

thick. 3' x 3' x 3' = 27 cubic feet. 27 cubic feet = 1 cubic yard.

The formula is: L'

x W' x T' ÷ 27 = cubic yards.

-or-

L' x W' x T" ÷ 12 ÷27 = cubic yards (where T is in inches).

-or-

L" x W" x T" ÷ 1728 ÷ 27 = cubic yards (where

L, W, T, are in inches).

One cubic yard covers

324 square feet at 1" thickness.

One cubic yard is equal

to approximately 40 bags of 80 pound concrete mix (+/- .675 cu' per bag).

_____________________________________________________________________________________________

The table below shows

how many (approx.) 80 pound bags of concrete mix it will take to fill these

tubes used to construct concrete piers, etc.

|

Diameter of tube

|

Approx. number of 80

pd. bags

|

To fill this many feet

|

|

6"

|

1 bag

|

3 feet

|

|

8"

|

1 bag

|

2 feet

|

|

10"

|

1-1/2 bags

|

2 feet

|

|

12"

|

2-1/2 bags

|

2 feet

|

|

14"

|

1-1/2 bags

|

1 foot

|

|

30"

|

7-1/2 bags

|

1 foot

|

|

Formula: Diameter

squared x .7854 x height. For example 30" x 30" x .7854 =

706.86 ÷144 (to convert from

cubic inches to cubic feet) = 4.91 cu. ft. ÷ .675 cu. ft. per bag =

7.27 bags (rounded to 7-1/2).

|

One 80 pound bag of

concrete mix will cover an area approximately 2' x 4' x 1'.

Decimal and Millimeter equivalents

of fractions of an inch.

|

Inches

|

Inches

|

Mm

|

|

Inches

|

Inches

|

Mm

|

|

1/64

|

.01563

|

.397

|

|

33/64

|

.51563

|

13.097

|

|

1/32

|

.03125

|

.794

|

|

17/32

|

.53125

|

13.494

|

|

3/64

|

.04688

|

1.191

|

|

35/64

|

.54688

|

13.890

|

|

1/16

|

.0625

|

1.587

|

|

9/16

|

.5625

|

14.287

|

|

5/64

|

.07813

|

1.984

|

|

37/64

|

.57813

|

14.684

|

|

3/32

|

.09375

|

2.381

|

|

19/32

|

.59375

|

15.081

|

|

7/64

|

.10938

|

2.778

|

|

39/64

|

.60938

|

15.478

|

|

1/8

|

.125

|

3.175

|

|

5/8

|

.625

|

15.875

|

|

9/64

|

.14063

|

3.572

|

|

41/64

|

.64063

|

16.272

|

|

5/32

|

.15625

|

3.969

|

|

21/32

|

.65625

|

16.669

|

|

11/64

|

.17188

|

4.366

|

|

43/64

|

.67188

|

17.065

|

|

3/16

|

.1875

|

4.762

|

|

11/16

|

.6875

|

17.462

|

|

13/64

|

.20313

|

5.159

|

|

45/64

|

.70313

|

17.859

|

|

7/32

|

.21875

|

5.556

|

|

23/32

|

.71875

|

18.256

|

|

15/64

|

.23438

|

5.953

|

|

47/64

|

.73438

|

18.653

|

|

1/4

|

.250

|

6.350

|

|

3/4

|

.750

|

19.050

|

|

17/64

|

.26563

|

6.747

|

|

49/64

|

.76563

|

19.447

|

|

9/32

|

.28125

|

7.144

|

|

25/32

|

.78125

|

19.844

|

|

19/64

|

.29688

|

7.541

|

|

51/64

|

.79688

|

20.240

|

|

5/16

|

.3125

|

7.937

|

|

13/16

|

.8125

|

20.637

|

|

21/64

|

.32813

|

8.334

|

|

53/64

|

.82813

|

21.034

|

|

11/32

|

.34375

|

8.731

|

|

27/32

|

.84375

|

21.431

|

|

23/64

|

.35938

|

9.128

|

|

55/64

|

.85938

|

21.828

|

|

3/8

|

.375

|

9.525

|

|

7/8

|

.875

|

22.225

|

|

25/64

|

.39063

|

9.922

|

|

57/64

|

.89063

|

22.622

|

|

13/32

|

.40625

|

10.319

|

|

29/32

|

.90625

|

23.019

|

|

27/64

|

.42188

|

10.716

|

|

59/64

|

.92188

|

23.415

|

|

7/16

|

.4375

|

11.113

|

|

15/16

|

.9375

|

23.812

|

|

29/64

|

.45313

|

11.509

|

|

61/64

|

.95313

|

24.209

|

|

15/32

|

.46875

|

11.906

|

|

31/32

|

.96875

|

24.606

|

|

31/64

|

.48438

|

12.303

|

|

63/64

|

.98138

|

25.003

|

|

1/2

|

.500

|

12.700

|

|

1

|

1.0000

|

25.400

|

Formula: 1 divided by

the fraction = thousands of an inch. For example: 1 ÷ 4 = .250

Weights, Measures, and Miscellaneous

information.

Doubling the diameter of

a pipe increases its capacity four times.

A gallon of water

weights 8.336 pounds at 39 degrees Fahrenheit (point of greatest density).

A gallon of water

contains 231 cubic inches.

One cubic foot equals 1,728

inches.

One cubic foot of water

equals 7-1/2 gallons.

_______________________________________________________________________________________

Weight of some common

building materials.

|

Approximate weights of

dry wood by cubic foot (not board foot).

|

|

Ash

|

3-3/4

|

|

Red Oak

|

3-3/4

|

|

Birch

|

3-3/4

|

|

White Oak

|

4

|

|

Cedar

|

3-1/4

|

|

White Pine

|

2-1/3

|

|

Hemlock

|

2

|

|

Yellow Pine

|

3

|

|

Hickory

|

4

|

|

Poplar

|

2-1/2

|

|

Maple

|

3-1/2

|

|

Spruce

|

2-1/3

|

|

Metals: Approximate

weights per cubic foot, In pounds.

|

|

Brass

|

518

|

|

Copper

|

550

|

|

Cast Iron

|

450

|

|

Lead

|

710

|

|

Forged Steel

|

490

|

|

Tin

|

458

|

|

Aluminum

|

167

|

|

|

|

|

Concrete with Stone

Pounds per cu. ft. approx.

|

150

|

Loose Earth

Pounds per cu. ft. approx.

|

76

|

Dry Sand

Pounds per cu. ft. approx.

|

100

|

|

Frame wall with

1/2" drywall ppsf.

|

12

|

Floor sys 1/2"

plywood

with 3/4" flr. ppsf.

|

6

|

Roof Joist

1/2" plywood ppsf.

|

3

|

|

Cell Joist

1/2" drywall ppsf.

|

7

|

Glass 1/8" ppsf.

|

1.63

|

Glass 1/8" IG

ppsf

|

3.25

|

Metrics:

25.4 millimeter equals 1

inch.

2.54 centimeters equals 1 inch.

1 meter equals 39.37 inches.

1.6 kilometer equals 1 mile.

100 millimeter equals 1 centimeter

100 centimeter equals 1 meter

100 meter equals 1 kilometer

Approximate Conversions:

|

Inches

|

x

|

25=

|

Mm

|

|

Mm

mm

|

x

÷

|

0.04=

25.4=

|

Inches

Inches

|

|

Inches

|

x

|

2.5=

|

Cm

|

|

Cm

Cm

|

x

÷

|

0.4=

2.54=

|

Inches

Inches

|

|

Feet

|

x

|

30=

|

Cm

|

|

Meter

|

x

|

3.3=

|

Feet

|

|

Yards

|

x

|

0.9=

|

Meter

|

|

Meter

|

x

|

1.1=

|

Yards

|

|

Meter

|

x

|

1.6=

|

Kilometer

|

|

Kilometer

Kilometer

|

x

÷

|

0.6=

1.6=

|

Miles

Miles

|

|

Temperature

|

|

Celsius

|

Fahrenheit

|

|

-30

|

-22

|

|

-20

|

-4

|

|

-10

|

14

|

|

0

|

32

|

|

10

|

50

|

|

20

|

68

|

|

30

|

86

|

|

40

|

104

|

|

50

|

122

|

Temperature

Formula: °Fahrenheit - 32 x 0.56

= °Celsius

°Celsius x 1.8 + 32 = °Fahrenheit

Liquid:

1 ounce = 29.57 milliliters

1 quart = 0.95 liter

1 gallon = 3.79 liters

Cord Wood:

A cord of wood

measures 4' x 4' x 8'. Stacked cord contains 128 cubic feet by

measure. Actually is 80 cubic feet -the rest is air.

Weighs 3,000 pounds when dry, 4,000 pounds when wet. Seasoned wood is defined

as having 25% moisture content. Four percent of its energy is lost in the

evaporation process as it burns. Green wood is defined as having 80%

moisture content. Fifteen percent of its energy is lost in the

evaporation process.

Fuel energy BTU

comparison:

|

Heating Oil

|

138,000 BTU per gallon

(number 2 fuel oil)

|

|

Natural Gas

|

100,000 BTU per therm

|

|

L P gas

|

93,000 BTU per gallon

|

|

Mixed Hardwood

|

8,600 BTU per pound

based on seasoned wood weighing +/- 3,000 pd. per cord. 24,000,000 BTU

per cord (+/-)

|

Electrical

formulas: 1. Amps = Watts / Volts

2. Watts = Amps x Volts

3. Volts = Watts / Amps

Insulation: The

R-value of materials measures its resistance to heat flow. The higher the

R value, the better the resistance to heat flow.

The U-value is used to calculate heat loss.

Formula to find U-value is: 1 / R - value = U - value.

R-values of some common

building materials:

|

1" Fiberglass

batt,

Insulation

|

3.17

|

|

1" Expanded

polystyrene

|

4.00

|

|

1" Extruded

polystyrene

|

5.0

|

|

1"

Polyisocyanurate,

foil-faced

|

7.20

|

|

8" concrete block

|

1.11

|

|

1' Poured concrete

|

0.08

|

|

1" Soft wood

lumber

|

1.25

|

|

2x4 kds

|

4.38

|

|

2x6 kds

|

6.88

|

|

1/2" plywood

|

0.63

|

|

3/4" plywood

|

0.94

|

|

1/2" gypsum board

|

0.45

|

|

Window with

single glass

|

0.91

|

|

Windows with

IG glass 1/4" air sp.

|

1.69

|

|

Windows with 1/2"

Low E IG

|

3.13

|

|

Wood solid core

1-3/4 door

|

3.03

|

|

Metal ins. door

no glass

|

15.00

|

|

1/2" - 4"

air space

|

1.00

|

Temperature

Formula: Degrees Fahrenheit - 32 x 0.56 = degrees Celsius

Degrees Celsius x 1.8 + 32 = Degrees Fahrenheit

Liquid:

1 ounce = 29.57 milliliters

1 quart = 0.95 liter

1 gallon = 3.79 liters

Drywall

board installation: Approximate quantities needed for each item per 1,000' of

wall to cover.

32

pcs. 4 x 8 panels or 25 pcs. 4 x 10 or 21 pcs. 4 x 12.

138 pounds of ready mix compound.

370 lineal feet of tape.

2,000 nails or 1,275 screws.

______________________________________________________________________________

How to determine the handing of an interior passage or closet door.

Face

the door on the side of the door where in order to pen the door you must pull

it toward you. If the door knob is on the right it is a right hand

operating door. If the door knob is on the left it is a left hand

operating door.

Exterior

doors are identified in the same way, but it is also necessary to state that

the door is an inswing (swings into the building) or an outswing (swings to the

outside of the building).

The

active door of a Double door will also need to be identified -usually this is

done by viewing the door from the outside. It is either a left active or

right active panel.

It

is also wise to check with the manufacturer or sales person before ordering to

make sure that they do it the same way.

_______________________________________________________________________________

Miscellaneous

Math:

1.

Doubling a fraction makes it 1/2 its size.

For example: 2 x 1/16" = 1/32" and 2 x 1/4" = 1/8".

To

calculate the angles of multisided objects:

Divide

360 by the number of sides and ÷ by 2.

For example: An octagon -divide 360 by 8 (the number of sides) = 45 (the

center angle) ÷ by 2 = 22-1/2 (the other 2 angles).

koroth constructions

+91 8943009914 information courtesy

vipin sasidharan.